Inspect screen pack for contamination and replace if necessary. Rowe Equipment can provide a numerous types of mesh combinations in order to match your.

Dorstener Wire Tech has over 15 years experience in manufacturing extruder screens and.

. Screw Cooling Systems. Ensure barrel is filled with Dyna-Purge to prevent the chance of oxidation. The function of the screen pack in the extruder is to offer a pure and clear extrusion effect to remove unwanted particles.

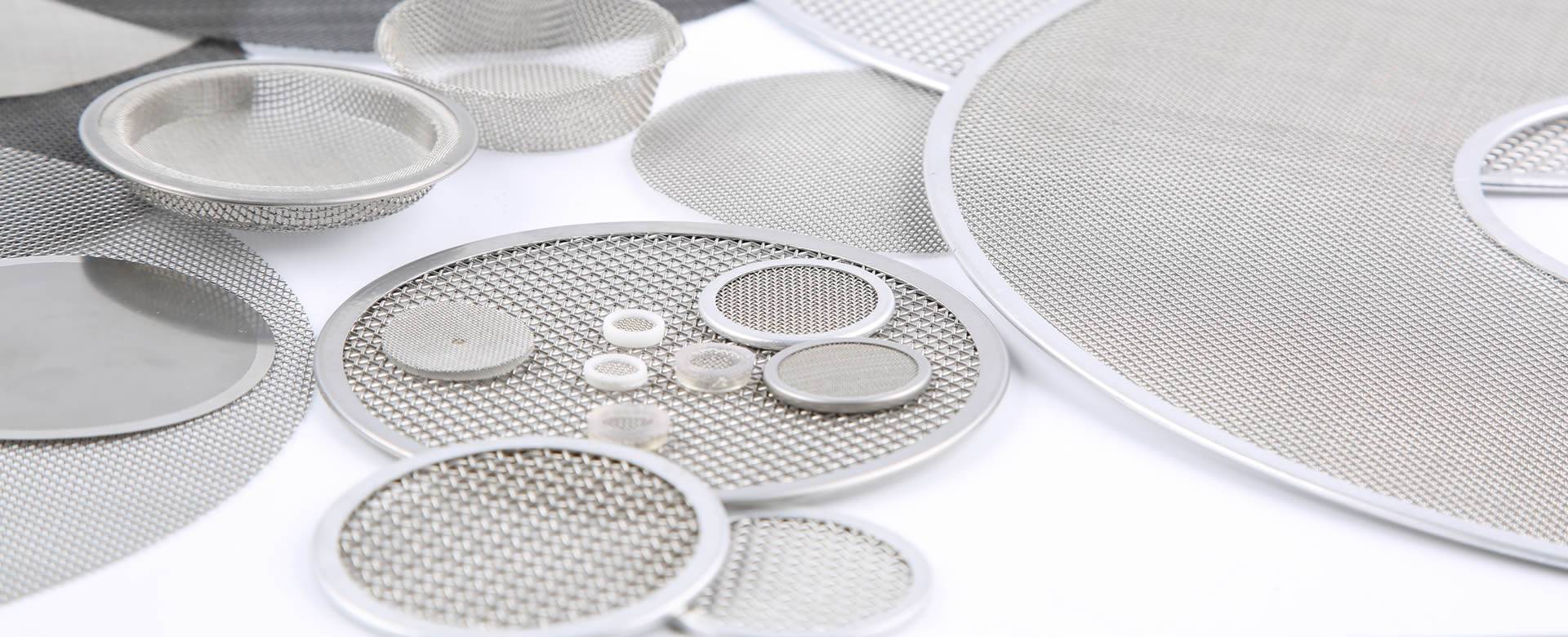

The holes in the breaker plate are normally 0318 cm 18 in to 0635 cm 14 in with a chamfer designed to give minimal obstruction to material flow. Also called polymer filter or melt filter screen. Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry.

However this new device is designed to created strong elongational flows for dispersive mixing by. Heating Cooling Elements. Polymer and fiber processing requires a wide range of filters and filter media for processing finishing and recycling the materials.

20 mesh 40 mesh 60 mesh and finally 20 mesh screen to support the 60 mesh. An extruder screen commonly referred to as a screen pack is a woven wire filtration system that is formed to meet the needs of the customer. A 20-mesh screen is typically used for the outside of the pack and can support up to a 150-mesh screen depending on the extrusion pressures.

Breaker plate is to support the screen pack and reduce screw beat. Breaker Plate Screen Pack. And customized service is also available according to your screen pack extrusion requirements.

The Mixing Breaker Plate MBP is similar to the standard breaker plate in that it is stationary in the extruder can hold a screen pack and also reduces screw beat. Standard Filson extruder filter screens are made of SS 304 SS 316L with a screen pack mesh size of 20-150 mesh. Extruder screens and polymer filters are just two of the varieties of filtration products offered by Dorstener Wire.

Table 1 Suggested Screw Design for Extrusion of Lubrizol TPUs Extruder Size 381 cm 1 12 in. DIE DESIGN. Screen packs help ensure your plant uses the same pack each and every time.

Inspect screen pack for contamination and replace if necessary. And the screens are in a symmetrical fashion which prevents the screen pack from accidentally being installed. The number and location of spot welds can be customized for your process.

8 30LD Performance LLDPE Dowlex 3310 285. Extruder Screen Pack Design. The screen pack also increases backpressure in the barrel Page 2 of 3 techtopic LyondellBasell Technical Tip The Extruder continued Zone 1 325F.

Mesh Size Number of Screens 24 3 24 1 60 3 60 1 24 3 24 1 Thinner films usually require up to 100 2 100 mesh screens to prevent metal grit and other particulate material from damaging the polishing rolls. Available in both single-layer and multi-layer configurations extruder screens remove impurities from melted plastic. Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry.

8 30LD Extruder Resin. Continue purging until the purge is clean and free of contamination. Their edges styles cover spot welded edges and aluminum framing around the spot welded edges.

If necessary adjust the airflow to stabilize the bubble. A hydraulic-powered automatic screen changer is always. These extruder screen packs are developed for ease of operation better inventory control and process control assurance.

Extruder screens can be made with both one layer of wire mesh or multiple layers. Drive System Moter Gear Box Transmission Extruder Screw and Barrel Functions or Advantage. Multilayer Extruder Screen packs are the different wire meshes cut to desired shapes and sizes and then assembled properly and spot welded with each other to form multilayer packs.

The screens in front of the finest screen are used to catch the larger particles to extend the life of the screen pack and to make the screen pack more rigid. Multi-layer is used when reground. Recommended for LLDPE and engineering resins in extrusion coating applications Also beneficial for lower temperature higher output polyolefin applications Offers superior melting rates and process stability.

Extruder screen pack is durable and rigid useful in fine extrusion process for prevention impurities also useful for water treatment plant. Cylindrical Extruder Screen Cylindrical extruder screen is widely applied in extrusion or filtration process in petrochemical pharmaceutical rubber and plastic industries. Slow down the process and open the air ring to increase wall size.

Multilayer extruder screen pack is made from several screens of different mesh sizes by welded them together. Stop screw rotation and reduce the temperature by lowering or turning off the heat zones. Extruder screen pack design For anyone who is a enthusiast of nail artwork but are certainly not utilized to the numerous coats of acrylic then this kind of design may possibly just perform very well for you.

Screen Pack and Screen Changer The following screen pack is typical for extruding APET sheeting. Purge through the die opening until Dyna-Purge appears in the film. A typical 20406020 screen pack has the order of screens from the end of the extruder screw.

JELLIFF CORPORATION can supply a complete range of sizes and shapes of screens in steel and stainless steel. Extruder screw design high output extruder output Screw and Barrel Wear It is often difficult to determine when to replace or repair a worn screw andor barrel. Extruder Screens Polymer Filters.

Also called polymer filter or melt filter screen. Screen pack but also serves as a mechanical seal between the barrel and the adapter to the die. Finer screens will need an additional support screen to avoid screen.

Also available are spot-welded and aluminum bound screen packs. Begin to purge and continue until the compound flushed out of the machine is clean and free of contamination. This pack screen filter is designed to keep away mixing of foreign particles in finally equipped extrusion product.

In the different mesh size screens the finest wire screen is in the center of the pack and the larger mesh opening screen is successively placed outer sides. The last coarse mesh prevents holes from being blown in the fine mesh screens in front of the breaker plate holes when high pressure is present. A single-layer is used when virgin material with few impurities is being processed.

Our fabricating facility located in Hickory North Carolina can fill your extruder screen requirements in a prompt and economical fashion. LLDPE Dowlex 3310 Conventional vs. Barrel Hopper Cooling System Elements.

China Extruder Screens And Screen Pack For Filtration And Plastic Extrusion Process China Extruder Screen Extruder Screen Pack

Extruder Screen Packs Download Scientific Diagram

Extruder Screens Ensure Plastic Processing A Clean Extrusion

Get Smart About Screens Plastics Technology

Extruder Screen The Ultimate Faq Guide Filson Filter

Stainless Steel Extruder Screen Pack Hightop Filter And Strainer

Extruder Screens Ensure Plastic Processing A Clean Extrusion

0 comments

Post a Comment